JHY PCB Blog Hub

Your Source for Expert PCB Design, Manufacturing, and Assembly Insights – Stay Informed with 2025 Trends!

Unmatched Excellence: Discover the Premier LED PCB Boards from China's Leading Factory

In the dynamic world of electronics, the demand for high-quality components is ever-increasing, and at the forefront of this evolution is the LED PCB board. As technology advances, manufacturers are striving to meet the demands for efficiency, durability, and superior performance. This blog explores the unmatched excellence of LED PCB boards produced by China's leading factory, renowned for their cutting-edge production techniques and commitment to quality.

Discover how these premier boards are revolutionizing the lighting industry and shaping the future of electronic applications. From innovative designs to enhanced functionality, China's top-tier LED PCB boards are not only setting new standards but also paving the way for sustainable and energy-efficient solutions in various sectors.

Join us as we delve into the world of LED PCB technology and uncover the exceptional benefits they offer in today's fast-paced market.

Discover how these premier boards are revolutionizing the lighting industry and shaping the future of electronic applications. From innovative designs to enhanced functionality, China's top-tier LED PCB boards are not only setting new standards but also paving the way for sustainable and energy-efficient solutions in various sectors.

Join us as we delve into the world of LED PCB technology and uncover the exceptional benefits they offer in today's fast-paced market.

The Rise of LED PCB Technology: Understanding Its Unmatched Excellence

The rise of LED PCB technology has revolutionized the electronics industry, showcasing unmatched excellence in both performance and efficiency. As technology advances, LED PCBs have become a vital component in various applications, from consumer electronics to industrial machinery. These boards offer superior thermal management and electrical conductivity, making them ideal for high-performance lighting solutions. The integration of LED technology into printed circuit boards allows for more compact designs, improved durability, and enhanced energy efficiency.

Moreover, the growing demand for environmentally friendly solutions has further propelled the popularity of LED PCBs. Manufacturers are increasingly focusing on sustainable practices, utilizing materials that reduce waste and energy consumption. As a result, LED PCBs not only deliver outstanding functionality but also align with the global push towards greener technologies. The commitment to innovation among leading factories in China ensures that the quality and performance of these products continue to meet the ever-evolving needs of the market, positioning them as the premier choice for businesses seeking unparalleled excellence in LED lighting solutions.

Unmatched Excellence: Discover the Premier LED PCB Boards from China's Leading Factory

| Specification | Description | Applications | Advantages | Material Type |

|---|---|---|---|---|

| FR-4 | Standard PCB material with good performance for LED applications | Lighting, Displays | Cost-effective, widely used | Epoxy Glass Fiber |

| ALuminum PCB | Enhanced thermal management for high-power applications | High Power LED, Automotive Lighting | Efficient heat dissipation, durable | Aluminum Base |

| Thermal Management PCB | Specially designed for optimal heat flow | Industrial Lighting, LED Displays | Enhanced longevity, reliability under stress | Various composite materials |

| Flexible PCB | Flexible design allows for custom shapes and space-saving | Wearable Devices, Mobile Lighting | Lightweight, versatile | Polyimide or PET Film |

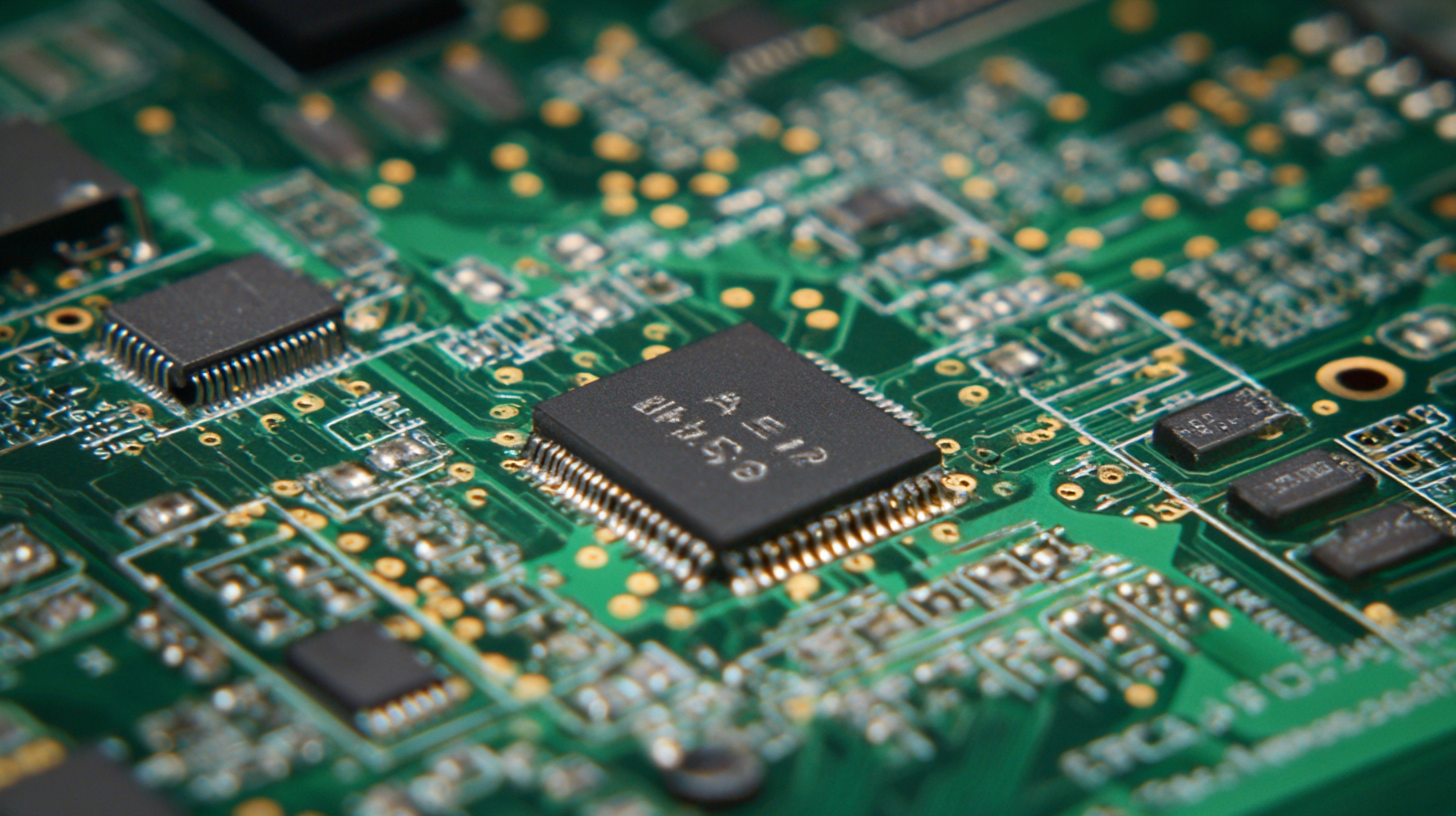

Key Features of Premier LED PCB Boards from China’s Leading Factory

The premier LED PCB boards from China's leading factory come with a range of key features that set them apart in the competitive market. These boards are designed with advanced thermal management technologies, ensuring optimal performance even in high-temperature environments. The use of innovative materials enhances both durability and efficiency, leading to longer product lifespans and lower energy consumption.

When selecting LED PCB boards, it’s crucial to consider the specific requirements of your application. **Tip:** Always check the thermal conductivity ratings to ensure the boards can handle your operational needs. Additionally, assess whether the substrate type matches your design requirements, as this impacts both performance and manufacturing costs.

Another noteworthy feature is the flexibility in design that these premier boards offer. With capabilities for custom layouts and integration of various components, manufacturers can achieve more compact and efficient designs. **Tip:** Collaborate closely with the manufacturer during the prototyping phase to optimize design and avoid potential pitfalls in production. This proactive approach can save time and resources, resulting in a more successful end product.

2025 Technology Development Trends: Innovations in LED and PCB Design

The year 2025 is projected to be a turning point for the LED and PCB industry, driven by rapid technological advancements and innovative design practices. According to a recent market analysis by Research and Markets, the global LED market is expected to reach $75.1 billion by 2025, showcasing a CAGR of 13.2% from 2020. This growth is largely attributed to the increasing demand for energy-efficient lighting solutions and the rising adoption of smart lighting systems in residential and commercial settings.

Moreover, advancements in PCB design are equally promising. The global PCB market is anticipated to grow to $87 billion by 2025, as reported by MarketsandMarkets. The integration of flexible PCBs and the rise of IoT-enabled devices are driving this surge. Companies are innovating in materials and techniques to create PCBs that meet the needs of high-performance applications in sectors like automotive and consumer electronics. The convergence of LED technology with advanced PCB design opens new avenues for efficiency, versatility, and sustainability, positioning these industries for a transformative future.

Exploring Alternatives: Comparing LED PCB Boards with Traditional Options

When it comes to LED PCB boards, the advantages over traditional options are becoming increasingly clear. Recent industry reports indicate that the global LED PCB market is expected to reach $10 billion by 2025, outpacing traditional PCB growth rates by nearly 15%. This shift is primarily due to the superior thermal management and energy efficiency offered by LED PCBs, making them indispensable for modern lighting solutions. In addition, the longevity of LED boards—often exceeding 50,000 hours—far eclipses that of standard options, which typically last only around 10,000 hours.

Tip: When selecting LED PCBs, look for ones with a high thermal conductivity rating (over 1.5 W/mK) to enhance performance and lifespan.

Comparing costs, LED PCBs can often appear higher initially, but their operational savings become apparent over time. For instance, the energy consumption of LED lighting is nearly 75% lower than incandescent lighting, contributing to long-term cost efficiency. Furthermore, with advancements in manufacturing, sourcing high-quality LED PCBs from leading factories in China ensures competitiveness without compromising quality.

Tip: Consider partnering directly with manufacturers to negotiate bulk purchasing, which can yield significant savings on LED PCB costs.

Sustainability in LED PCB Production: The Future of Eco-friendly Technologies

In the rapidly evolving world of technology, sustainability is taking center stage, especially in the production of LED PCB (Printed Circuit Boards). As consumers increasingly prioritize eco-friendly practices, manufacturers are adapting by embracing green technologies in their production processes. This shift not only addresses environmental concerns but also creates innovative pathways for enhanced efficiency and performance.

China's leading LED PCB factories are at the forefront of this movement. By utilizing sustainable materials and energy-efficient methods, they are setting new standards in the industry. The integration of recyclable materials and low-energy manufacturing techniques reduces waste and lowers the carbon footprint, promoting a circular economy. These advancements not only contribute to a healthier planet but also ensure that businesses remain competitive in an eco-conscious market.

Moreover, these eco-friendly practices are complemented by cutting-edge technology, allowing for high-quality LED PCBs that meet global standards. With an emphasis on sustainability, manufacturers are not only enhancing product durability but also fostering a culture of responsibility towards environmental stewardship. As these factories continue to innovate, they are redefining the future of LED PCB production, making sustainability a core aspect of technological advancement.