JHY PCB Blog Hub

Your Source for Expert PCB Design, Manufacturing, and Assembly Insights – Stay Informed with 2025 Trends!

Why Choose Flexible Printed Circuit Boards for Your Projects?

In the evolving landscape of electronics, the importance of the Flexible Printed Circuit Board cannot be overstated. Dr. Emily Chen, a leading expert in circuit design, once stated, "Flexible PCBs are the future; they adapt to your needs." This adaptability is key for various industries, from consumer electronics to medical devices.

Flexibility is not just physical; it encapsulates innovation. With a Flexible Printed Circuit Board, designers can create intricate layouts that fit into compact spaces. This versatility allows for enhanced performance and reliability in demanding environments. Yet, there are challenges in material selection and manufacturing processes that require careful consideration.

Many projects still overlook the potential of Flexible Printed Circuit Boards. The tendency to stick with traditional rigid boards often limits creativity and functionality. As the industry grows, embracing the unique features of these flexible boards may lead to breakthroughs in design and application. Reflecting on these choices is vital for future advancements.

Benefits of Flexible Printed Circuit Boards in Modern Electronics

Flexible Printed Circuit Boards (FPCBs) are changing the landscape of modern electronics. Their adaptability makes them ideal for compact devices. Compared to traditional rigid PCBs, FPCBs save space. They can bend and twist, allowing for more creative designs. This is crucial as devices become smaller and more complex.

According to a report by Research and Markets, the global flexible printed circuit board market is projected to reach USD 65.14 billion by 2026. This growth is driven by the rising demand for lightweight and space-saving electronics. FPCBs are commonly used in smartphones, wearables, and medical devices. These applications benefit from FPCBs' ability to fit into challenging spaces where conventional boards cannot.

However, challenges exist. FPCBs can be more costly to manufacture than traditional boards. Their production requires specialized skills and equipment. This can lead to quality control issues. Manufacturers must be cautious during the design and production phases. Ensuring reliability is crucial in critical applications. As technology advances, improving production processes will be important.

Applications of Flexible Printed Circuit Boards Across Various Industries

Flexible printed circuit boards (FPCBs) are reshaping many industries. Their versatility enables various applications, from consumer electronics to medical devices. In consumer gadgets, FPCBs reduce space and increase functionality. They fit into complex shapes, making them ideal for modern designs. Moreover, in the automotive field, flexible circuits help manage intricate electrical systems.

In the medical realm, FPCBs enhance device performance. They are lightweight and can be integrated into wearable technologies. Heart monitors and insulin pumps benefit from their compact nature. However, durability can be an issue. Not all flexible circuits endure harsh environments. It's crucial to evaluate their specifications carefully.

Tip: Always consider the environment where your FPCB will be used. Heat, moisture, and bending can affect performance.

Flexible circuits are also found in aerospace. They contribute to avionics and satellite systems. These applications require reliable performance. The challenges often include ensuring signal integrity and shielding. Careful material selection is vital for success.

Tip: Work with prototypes during the design phase. Testing can reveal unexpected issues. Early adjustments can save time and resources later on.

Why Choose Flexible Printed Circuit Boards for Your Projects? - Applications of Flexible Printed Circuit Boards Across Various Industries

| Industry | Application | Benefits of FPCB | Challenges |

|---|---|---|---|

| Consumer Electronics | Smartphones, Tablets | Lightweight, High-Density Connections | Manufacturing Complexity |

| Automotive | Dashboard Controls, Sensors | Flexibility, Durability | High Temperature Requirements |

| Medical Devices | Portable Diagnostic Equipment | Miniaturization, Precision | Regulatory Compliance |

| Aerospace | Navigation Systems, Sensors | Lightweight, Efficient Space Use | Cost and Durability Concerns |

| Telecommunications | Signal Processors, Antennas | High Performance, Reduced Signal Loss | Design Limitations |

Key Design Considerations When Choosing Flexible Printed Circuit Boards

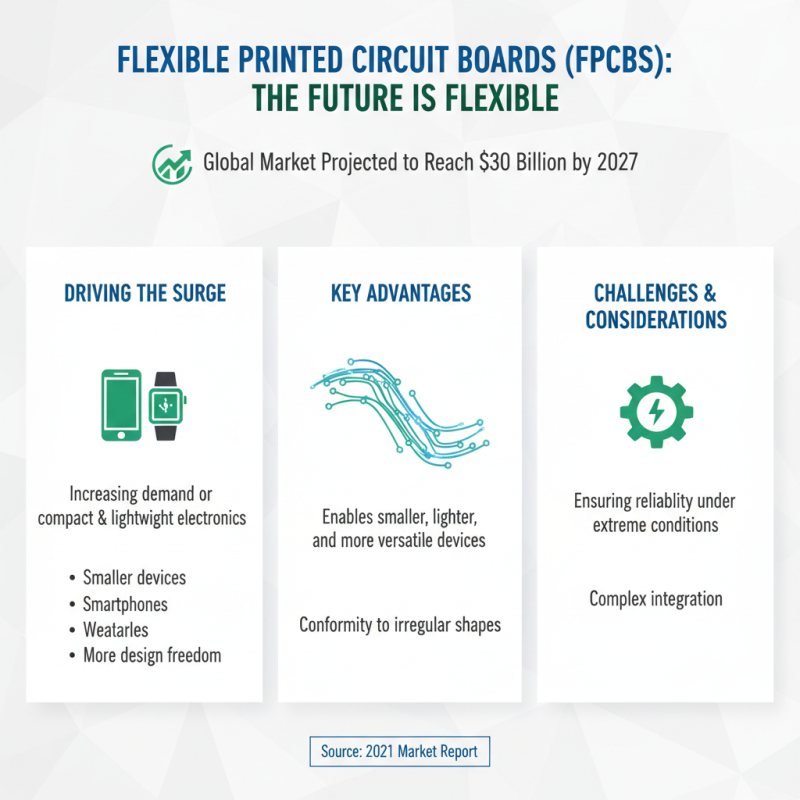

When selecting flexible printed circuit boards (FPCBs) for projects, several design aspects must be carefully considered. These boards offer significant advantages, like weight reduction and improved space efficiency. According to industry reports, the flexible circuit market is expected to reach $30 billion by 2027, illustrating their growing relevance in various applications.

Material selection is crucial. Common materials include polyimide and polyester. Each material has its properties that affect performance, such as thermal stability and dielectric strength. For instance, polyimide is well-suited for high-temperature environments. However, designers must evaluate whether the cost justifies the performance gain. Sometimes, the balance isn’t clear-cut.

**Tip:** Prototype with different materials. Testing can reveal which suits your design best.

Moreover, the thickness of the circuit can impact flexibility and durability. Many manufacturers offer a range of thicknesses, but thicker boards can be less flexible. The desired application must guide these decisions. While a thick board may seem durable, it could limit design flexibility.

**Tip:** Always account for bending radius in your layout. It can prevent potential failures later.

Ultimately, ensuring the FPCB meets both the mechanical and electrical requirements can prove challenging. With continuous advancements, it is vital to stay updated on the latest technologies and standards. Embracing a thorough review process can lead to better outcomes.

Cost-Effectiveness and Manufacturing Efficiency of Flexible Circuits

Flexible printed circuit boards (FPCBs) offer remarkable cost-effectiveness and manufacturing efficiency. These circuits are lightweight and adaptable, making them ideal for various applications. They can easily fit into tight spaces, which is often crucial for modern electronics.

The manufacturing process of FPCBs is streamlined, reducing costs significantly. They require fewer materials than traditional rigid boards. This cuts down on waste and minimizes production expenses. However, it’s essential to maintain quality during manufacturing. Poor quality control might lead to failures in critical applications.

Designing flexible circuits does pose challenges. Engineers must think creatively to ensure functionality. Geometric constraints can limit design options. Yet, this is also an opportunity for innovation. Embracing the possibilities of flexibility can lead to groundbreaking solutions. Balancing cost and performance is key, and flexibility can be both an advantage and a challenge.

Future Trends and Innovations in Flexible Printed Circuit Board Technology

Flexible Printed Circuit Boards (FPCBs) are gaining momentum in technology. According to a 2021 market report, the global flexible PCB market is projected to reach $30 billion by 2027. This surge is due to the increasing demand for compact and lightweight electronic devices. FPCBs enable devices like smartphones and wearables to be smaller, offering designers more freedom. However, integrating these boards can sometimes present challenges, such as ensuring reliability in extreme conditions.

Innovations are shaping the future of FPCB technology. New materials and manufacturing processes are emerging, enhancing performance. A recent study indicated a 15% increase in thermal conductivity with new substrates. However, the industry faces issues like scalability. This can slow down production and increase costs, leading to potential delays. Moreover, as technology evolves, the recycling of FPCBs raises concerns, with only 2% currently being recycled. Hence, while the future looks promising, several aspects still need attention.

Related Posts

-

Choosing the Right Manufacturer for Best Flex Circuit Boards with Key Comparisons

-

7 Essential Tips for Sourcing the Best Quick Turn PCB Boards Globally

-

Future of Printed Circuit Boards: Innovations and Market Trends Shaping 2025 Top+ Digital Landscape

-

Essential Checklist for Choosing the Best Pcb Printed Circuit Board for Your Project

-

Maximizing After Sales Support and Minimizing Repair Costs with Best PCB Prototype Board Solutions

-

How to Select the Right Quick Turn PCB Boards for Your Project Needs