JHY PCB Blog Hub

Your Source for Expert PCB Design, Manufacturing, and Assembly Insights – Stay Informed with 2025 Trends!

How to Choose the Best Injection Machine Robot for Your Needs?

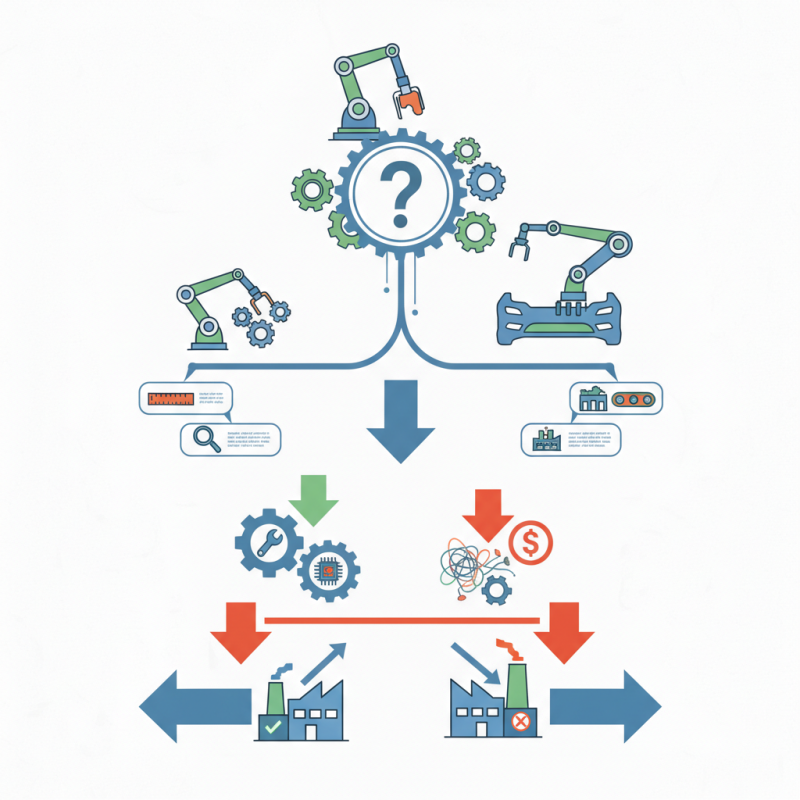

In the competitive world of manufacturing, selecting the right Injection Machine Robot is crucial. According to industry expert Dr. Alice Chen, “The right robot can significantly enhance efficiency.” But how do you determine which robot suits your needs? The complexity of options available can be overwhelming.

Consider the specific needs of your production line. Are you producing small parts or larger components? The size and scale of your operations will influence the type of Injection Machine Robot that is best for you. Each robot has unique capabilities and limitations. Assessing these factors is essential to avoid missteps that could lead to operational inefficiencies.

Another important element is compatibility with existing technology. You might find a robot that seems perfect but fails to integrate smoothly. This can result in unforeseen expenses and delays. Evaluating all aspects of an Injection Machine Robot before making a choice allows for better alignment with production goals. In the fast-paced manufacturing landscape, proper choices lead to success, but oversight can lead to costly setbacks.

Understanding Different Types of Injection Machine Robots Available Today

When selecting an injection machine robot, understanding the different types available is crucial. There are mainly two categories: Cartesian robots and robotic arms. Cartesian robots move along three axes, creating a simple and efficient path. These are ideal for straightforward applications, offering accuracy without complexity. Meanwhile, robotic arms provide greater flexibility. They can reach and manipulate complex shapes, making them better suited for varied tasks.

Another type to consider is the collaborative robot, or cobot. Cobots work alongside human operators, enhancing safety and productivity. Their ability to sense nearby human workers creates a safer work environment. However, reliance on this technology raises questions. How often do we assess their effectiveness compared to traditional robots? It's essential to evaluate their integration into existing workflows.

Then, there are specialized robots designed for niche applications. These may offer enhanced capabilities, yet they can also introduce complications. Often, these robots require extensive training and maintenance. Are they worth the investment if the tasks change frequently? This unpredictability can lead to challenges in scalability. Understanding these types will help you make more informed choices for your specific needs.

Key Specifications to Consider When Selecting an Injection Robot

When selecting an injection robot, key specifications play a critical role. The payload capacity is essential. It determines how much weight the robot can handle. If your molds are heavier than expected, you might face issues. It's vital to align the robot’s capability with your production needs. This avoids potential losses and inefficiencies.

Another important feature is the degrees of freedom. A robot with more joints offers greater flexibility. This can lead to improved accuracy and efficiency. If you opt for a lower degree of freedom, you may find limitations in your production line. It's a trade-off that deserves careful thought.

Look closely at the cycle time as well. A robot that operates too slowly may hinder overall output. Yet, if it's too fast, product quality might suffer. Finding the right balance is crucial. Reviewing real-world performance can unveil these complexities. It's not just about picking the machine; it’s about ensuring it fits your operation.

How to Choose the Best Injection Machine Robot for Your Needs?

| Specification | Description | Importance |

|---|---|---|

| Payload Capacity | The maximum weight the robot can handle. | High |

| Reach | The maximum distance the robot can extend its arm. | Medium |

| Speed | The speed at which the robot can operate. | High |

| Repeatability | The accuracy with which a robot can perform the same movement multiple times. | High |

| Control System | The technology used for controlling the robot’s movements. | Medium |

| Integration | How easily the robot can be integrated with existing systems. | High |

| Safety Features | Built-in mechanisms to ensure safe operation. | High |

| Cost | The total investment required for the robot. | High |

Evaluating Industry-Specific Requirements for Injection Machine Robots

When selecting an injection machine robot, industry-specific requirements are crucial. Different sectors have unique needs. For example, the automotive industry often demands precision and speed. In contrast, the medical field prioritizes sterilization and safety. Understanding these nuances can guide your choice.

Another consideration is the production volume. High-output industries might need robots capable of continuous operation. This could lead to higher initial costs but better long-term efficiency. On the other hand, smaller operations might not need such advanced features. They may benefit from simpler, more affordable models.

Maintenance is another area worth pondering. Some robots require specialized training for upkeep. This can lead to unexpected costs. Others offer more user-friendly maintenance options. It's essential to weigh these factors. Take time to analyze how well a choice fits your specific production line. This reflection can save resources in the long run.

Analyzing Cost vs. Performance in Injection Robot Selection

When selecting an injection machine robot, cost and performance are crucial factors. Many manufacturers face budget constraints. However, choosing the cheapest option may lead to performance issues later. Consider the initial cost alongside long-term efficiency. A low price might come with lower reliability, resulting in increased downtime and repairs.

Performance metrics should not be overlooked. Speed, precision, and flexibility are vital for optimal productivity. Examine how quickly the robot can complete tasks. Higher speed often correlates with better output. However, speed should not come at the cost of accuracy. Some machines are faster but less accurate. Be wary of trade-offs that may hinder your operations.

Evaluate your specific needs carefully. Do you require an adaptable robot for varied tasks or a dedicated machine? Sometimes, versatile robots may have a higher upfront cost, but they can save money in the long run. Balancing these factors can be challenging. It's essential to analyze the total cost of ownership, including maintenance and potential upgrades. This reflection can guide you toward a more informed decision.

Future Trends in Injection Machine Robotics and Their Implications

The field of injection machine robotics is evolving rapidly. These advancements are driven by the need for efficiency and precision. Future trends include smarter robots that adapt to various tasks. They will utilize AI to enhance performance and reduce errors. This can lead to greater productivity in manufacturing processes.

When selecting an injection machine robot, consider its adaptability. Will it meet your current and future needs? Look at its programming flexibility. This can be crucial as production requirements change. In the next few years, automation will become even more prevalent. Robots that can learn and improve will stand out in the market.

Tips for choosing include assessing the robot's usability. Is the interface user-friendly? Also, evaluate the support and training offered. A strong support system is essential for smooth operation. Consider the robot's energy consumption. Efficient robots lower operating costs over time. Balancing these factors can greatly influence your decision-making process.