JHY PCB Blog Hub

Your Source for Expert PCB Design, Manufacturing, and Assembly Insights – Stay Informed with 2025 Trends!

Why Choose a Rubber Air Hose for Your Projects?

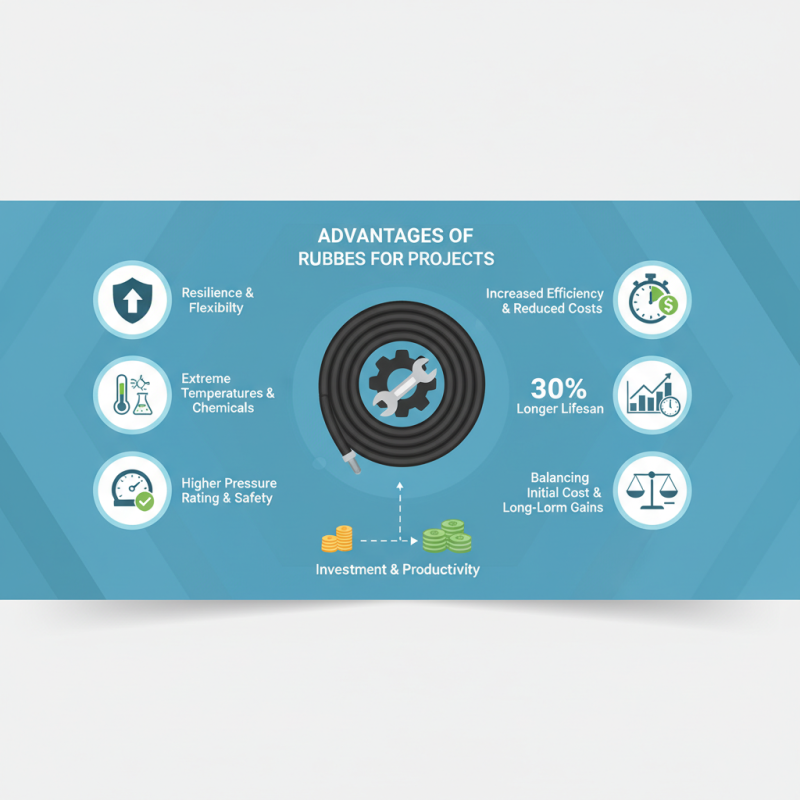

Choosing the right tool for any project is crucial. A rubber air hose stands out in the market for its resilience and flexibility. Industry expert John Thompson emphasizes, "A reliable rubber air hose can enhance efficiency and reduce maintenance costs significantly." Recent studies show that rubber hoses last up to 30% longer than their PVC counterparts.

These air hoses maintain performance under harsh conditions. They resist extreme temperatures and harsh chemicals. The ability to withstand such environments makes them a favorite. Additionally, rubber air hoses are often rated for higher pressures, ensuring safer operations. Yet, not all projects will benefit from them. Some may find the weight of rubber hoses cumbersome compared to lighter alternatives.

Investing in a rubber air hose requires careful consideration. An informed choice can lead to increased productivity. However, some users report that these hoses may be more expensive upfront. This cost needs justification in terms of longevity and efficiency. Balancing initial costs with long-term gains becomes essential.

Benefits of Using Rubber Air Hoses in Industrial Applications

Rubber air hoses are vital in many industrial settings. Their durability and flexibility make them a great choice for various applications. According to industry reports, rubber hoses can withstand extreme temperatures, ranging from -20°F to 190°F. This resilience helps them excel in diverse environments, from freezing cold to high heat.

One study indicated that rubber air hoses can last up to three times longer than their PVC counterparts. This longevity can translate to significant cost savings. However, the initial investment may be higher. Companies need to weigh these factors carefully. A cheaper option might seem appealing, but it can lead to frequent replacements.

Moreover, rubber hoses are less likely to kink, which is a common issue in pneumatic systems. A kinked hose can disrupt airflow and reduce efficiency. In fact, a report noted that up to 15% of compressed air can be lost through leaks in improperly maintained hoses. These details highlight the importance of quality in selecting air hoses. The choice can dramatically affect overall productivity.

Benefits of Using Rubber Air Hoses in Industrial Applications

Durability and Flexibility: Key Features of Rubber Air Hoses

When it comes to air hoses, rubber options stand out for their unique qualities. Durability is one of their key features. Unlike plastic or PVC hoses, rubber can withstand tough environments. It resists punctures and abrasions, making it ideal for outdoor use. Imagine working in a construction zone with heavy machinery around. A rubber air hose can handle that stress. It won’t crack or crumble under pressure.

Flexibility is another significant aspect. Rubber hoses remain pliable even in extreme temperatures. They don’t become stiff in the cold or overly soft in the heat. This flexibility makes them easier to maneuver. Cumbersome hoses can slow you down. A lightweight, flexible option allows for easier handling and less fatigue during use. You can easily coil or uncoil it, simplifying storage and transport.

However, it's essential to note that not all rubber air hoses are created equal. Some may become less flexible over time, especially if not properly maintained. While they are built to last, neglect can lead to reduced performance. Regular inspection is crucial to ensure they continue to work effectively. Even a small tear can lead to significant issues. Reflecting on your equipment’s condition can save you time and money later on.

Temperature Resistance: How Rubber Air Hoses Excel Under Extreme Conditions

When it comes to extreme conditions, rubber air hoses stand out. Unlike other materials, rubber can withstand temperature fluctuations from -40°F to 190°F. This exceptional range makes it ideal for outdoor projects. According to industry reports, rubber hoses maintain flexibility, ensuring they don’t become rigid in cold weather. This adaptability allows for efficient operations, even in harsh environments.

Tips: Always inspect your hose regularly. Look for cracks or wear that can indicate fatigue.

Moreover, rubber air hoses exhibit high resistance to abrasion and wear. This durability is crucial in industrial settings. A study found that rubber hoses can last over five years under heavy use. However, improper storage can lead to deterioration. Avoid leaving them in sunlight or extreme heat.

Another consideration is weight. Rubber hoses can be heavier than their PVC counterparts. This means they can be harder to maneuver in tight spaces. Finding a balance between durability and ease of use is vital. Always consider your project's specific needs for optimal performance.

Comparative Analysis: Rubber vs. PVC Air Hoses in Performance Tests

When choosing air hoses for your projects, rubber and PVC are common materials. Both options have unique advantages and disadvantages in performance. Rubber air hoses tend to perform better in extreme temperatures. They remain flexible and durable, even in cold conditions. In contrast, PVC hoses can become stiff when temperatures drop low.

In terms of pressure resistance, rubber hoses often excel. They can handle higher pressures without bulging or wearing out. PVC hoses might struggle under the same conditions, leading to premature failure. However, PVC hoses are lighter and easier to handle, which can be an essential factor for some users.

Durability is another area of concern. Rubber hoses can withstand abrasions better than PVC, making them ideal for rugged environments. However, they can be heavier and more challenging to roll up. On the other hand, while PVC hoses might not last as long, they can be more affordable upfront. Users might find themselves evaluating short-term costs versus long-term investments. Balancing these factors is critical when deciding.

Cost-Effectiveness: Longevity and Maintenance of Rubber Air Hoses

Rubber air hoses stand out for their cost-effectiveness. They can last for years with proper care. This means fewer replacements and less waste. Often, users overlook the longevity aspect. Many might prefer cheaper options that wear out quickly. However, the initial savings can vanish with frequent replacements.

Maintenance of rubber air hoses is relatively simple, which adds to their value. Regular checks for leaks or wear can prolong their lifespan. It's crucial to store them properly, away from harsh conditions. Some users neglect the need for routine care, leading to premature failure. It's a common oversight that can be easily avoided.

Investing in a rubber air hose may seem more costly upfront. Yet, in the long run, it often proves to be a better choice. The durability of rubber hoses can handle various projects with ease. Users can feel confident in their reliability for challenging tasks. Finding the right balance between price and quality is essential. It’s worth considering how much time and money can be saved.

Why Choose a Rubber Air Hose for Your Projects? - Cost-Effectiveness: Longevity and Maintenance of Rubber Air Hoses

| Feature | Rubber Air Hose | Other Hose Types |

|---|---|---|

| Longevity | 5-10 years | 1-5 years |

| Temperature Resistance | -40°F to 190°F | -20°F to 150°F |

| Flexibility | Excellent | Moderate |

| Resistance to Abrasion | High | Low |

| Maintenance Required | Low | High |

| Cost (per foot) | $0.75 - $1.50 | $0.50 - $1.00 |