JHY PCB Blog Hub

Your Source for Expert PCB Design, Manufacturing, and Assembly Insights – Stay Informed with 2025 Trends!

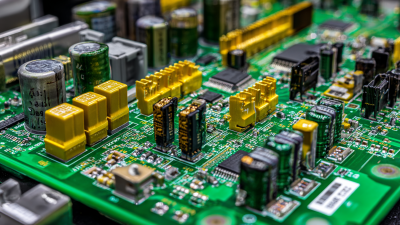

Unlocking the Advantages of PCB Board Assembly for Global Procurement Success

In today's rapidly evolving global marketplace, companies are increasingly recognizing the pivotal role of PCB Board Assembly in streamlining their procurement processes and enhancing product efficiency. As businesses strive for competitive advantage, the demand for high-quality, reliable electronic components has surged, prompting manufacturers and procurement specialists to seek innovative solutions to optimize their supply chains. PCB Board Assembly not only facilitates the integration of complex electronic designs but also contributes to reducing costs and improving quality control, making it a crucial element in the success of global procurement strategies. By unlocking the advantages of PCB Board Assembly, organizations can better position themselves in the market, ensuring they deliver superior products that meet customer expectations while navigating the challenges of global sourcing.

The Rising Demand for PCB Board Assembly in Global Supply Chains

The rising demand for PCB board assembly within global supply chains is reflective of broader trends in manufacturing, particularly as industries adapt to new technological advancements. Recent reports indicate that sectors like electric vehicles and electronics are driving this surge, particularly in regions where industrial growth is essential. In Thailand, for example, the manufacturing sector, which has historically been a vital part of its economy, is now evolving to meet new needs driven by government initiatives aimed at enhancing efficiency and technological capacity. This shift opens doors for PCB board assembly to play a critical role in supplying the components necessary for modern electronics.

As companies seek to optimize their supply chains, the assembly of PCBs offers improved production efficiency, which is particularly pressing given recent challenges in the industry. The integration of advanced manufacturing techniques can alleviate some of the pain points associated with supply-side inefficiencies. Consequently, organizations that embrace PCB board assembly not only tap into a growing market but also position themselves strategically to enhance their operational effectiveness, setting the stage for sustainable growth in a competitive global landscape.

Rising Demand for PCB Board Assembly in Global Supply Chains

This chart illustrates the increase in demand for PCB board assembly over the years in various industries, highlighting the growth trend driven by global procurement strategies.

Key Benefits of Utilizing PCB Assembly Services for Cost Efficiency

The ever-evolving landscape of global procurement necessitates innovative solutions, and one prime example is the adoption of PCB board assembly services. By utilizing these services, companies can leverage significant cost efficiencies in their manufacturing processes. This not only reduces the overall expense of production but also streamlines supply chain management, allowing businesses to allocate resources more effectively.

Moreover, outsourcing PCB assembly enables organizations to focus on their core competencies. With specialized firms handling the intricate assembly process, companies can significantly cut down on labor costs and overhead associated with maintaining an in-house assembly line. This shift not only enhances productivity but also fosters flexibility, allowing businesses to respond swiftly to market demands while maintaining high-quality standards. Embracing PCB assembly services can undeniably pave the way for enhanced financial stability and competitive advantage in a global marketplace.

Technological Advancements in PCB Assembly: Driving Innovation and Quality

The landscape of PCB assembly has evolved dramatically due to technological advancements, propelling innovation and enhancing the quality of products. Modern techniques such as automated assembly processes and advanced inspection technologies have significantly reduced human error and improved precision.

These innovations not only streamline production but also facilitate the creation of complex designs that were previously challenging to achieve. As a result, manufacturers can deliver high-quality electronics that meet the stringent demands of global markets.

Additionally, the integration of smart technologies and data analytics in PCB assembly processes promotes greater efficiency and adaptability. Real-time monitoring systems enable manufacturers to track production metrics and quickly identify areas for improvement.

This agility allows for faster response times to market changes and customer needs. With these technological advancements, businesses can ensure higher reliability in their products, paving the way for successful global procurement strategies and establishing a competitive edge in the ever-evolving electronics industry.

The Role of Lean Manufacturing Principles in Optimizing PCB Production

Lean manufacturing principles play a crucial role in optimizing PCB board assembly, enabling companies to enhance efficiency and reduce waste in the production process. By adopting lean methodologies, manufacturers can streamline operations, minimize lead times, and improve product quality. This approach emphasizes value creation by focusing on processes that directly add to the customer’s satisfaction, while systematically eliminating activities that do not contribute to this goal.

Implementing lean manufacturing in PCB production not only fosters a culture of continuous improvement but also enhances collaboration among teams. Techniques such as Just-In-Time (JIT) inventory management and the 5S methodology help in maintaining organized workflows and reducing excess stock. As a result, companies can respond more swiftly to changing market demands, resulting in a more agile supply chain. By deeply embedding lean principles into their PCB assembly processes, organizations position themselves for greater success in the global procurement landscape.

Unlocking the Advantages of PCB Board Assembly for Global Procurement Success

| Dimension | Lean Manufacturing Principle | Impact on PCB Assembly | Benefits for Global Procurement |

|---|---|---|---|

| Reduction of Waste | Value Stream Mapping | Streamlined processes lead to less material wastage. | Lower production costs, better pricing for customers. |

| Inventory Management | Just-In-Time (JIT) | Minimized inventory reduces overhead and storage costs. | Enhanced cash flow and reduced lead times. |

| Quality Assurance | Continuous Improvement (Kaizen) | Regular assessment improves product quality and reliability. | Increased customer satisfaction and repeat business. |

| Process Efficiency | 5S Methodology | Improved workplace organization enhances productivity. | Faster turnaround times for orders, leading to quicker market delivery. |

| Supplier Relationships | Collaborative Partnerships | Stronger collaboration improves communication and trust. | More reliable supply chains and better negotiation outcomes. |

Strategic Partnerships: Enhancing Procurement Success through PCB Collaboration

Strategic partnerships in the PCB board assembly sector are key to navigating the complexities of global procurement. As industries pivot towards sustainable practices, companies like Elephantech are at the forefront, leveraging innovative technologies like metal inkjet printing to meet the surging demand for eco-friendly PCBs. A report from IDC predicts that the PCB market will grow at a CAGR of 4.1% from 2023 to 2028, underscoring the importance of collaboration to capture market opportunities and enhance competitive advantage.

Strategic partnerships in the PCB board assembly sector are key to navigating the complexities of global procurement. As industries pivot towards sustainable practices, companies like Elephantech are at the forefront, leveraging innovative technologies like metal inkjet printing to meet the surging demand for eco-friendly PCBs. A report from IDC predicts that the PCB market will grow at a CAGR of 4.1% from 2023 to 2028, underscoring the importance of collaboration to capture market opportunities and enhance competitive advantage.

Collaboration fosters not only innovation but also operational efficiency. In the semiconductor industry, strategic partnerships are vital for addressing the ongoing supply chain challenges. Reports indicate that collaborative efforts can lead to a 15% reduction in production costs, allowing companies to allocate resources more effectively. By aligning goals and expertise through partnerships, firms can share risks and resources, ultimately enhancing their procurement strategies and driving sustained growth in a highly competitive landscape.

As technology continues to evolve and demand increases, the emphasis on strategic partnerships will only intensify. Companies that embrace collaborative approaches in PCB manufacturing and assembly will be better positioned to achieve procurement success while promoting sustainable practices in a rapidly changing global marketplace.

Related Posts

-

Solutions for Efficient Best Printed Board Assembly Manufacturing

-

The Ultimate Guide to Optimizing Printed Board Assembly for Maximum Efficiency and Cost Savings

-

2025 Global Insights on Best Prototype Circuit Board Manufacturing Trends

-

Navigating the 2025 Tech Landscape: Key Strategies for Sourcing the Best PCB Circuit Boards Globally

-

Maximizing After Sales Support and Minimizing Repair Costs with Best PCB Prototype Board Solutions

-

The Ultimate Guide to Circuit Board Assembly Strategies for Global Buyers