JHY PCB Blog Hub

Your Source for Expert PCB Design, Manufacturing, and Assembly Insights – Stay Informed with 2025 Trends!

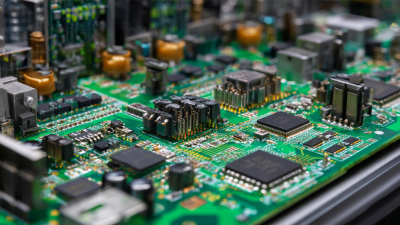

Unlocking the Future: How Advanced Circuit Board Fabrication is Revolutionizing Electronics with 5G and IoT Innovations

In the rapidly evolving landscape of electronics, Circuit Board Fabrication stands at the forefront of innovation, especially with the advent of 5G and IoT technologies. As devices become more interconnected, the demand for advanced circuit boards that can support higher frequencies, enhanced performance, and miniaturized designs is greater than ever. This article delves into the transformative impact of cutting-edge fabrication techniques that enable manufacturers to overcome the challenges posed by complex circuit designs and superior functionality.

By harnessing the latest advancements in materials and processes, engineers are able to unlock new possibilities for electronic devices, paving the way for smarter technologies that will redefine how we connect and communicate. The intersection of Circuit Board Fabrication and pioneering innovations is not just reshaping the electronics industry; it is also setting the stage for a more efficient and interconnected future.

Understanding the Basics of Advanced Circuit Board Fabrication Techniques

Advanced circuit board fabrication techniques are at the forefront of modern electronics, particularly in enhancing the capabilities of 5G and IoT technologies. These advanced methodologies integrate sophisticated materials and innovative designs to create highly efficient circuit boards. Techniques such as additive manufacturing, also known as 3D printing, allow for complex geometries and miniaturization that traditional methods struggle to achieve. This capability is crucial for developing compact devices that maintain performance in an increasingly connected world.

Advanced circuit board fabrication techniques are at the forefront of modern electronics, particularly in enhancing the capabilities of 5G and IoT technologies. These advanced methodologies integrate sophisticated materials and innovative designs to create highly efficient circuit boards. Techniques such as additive manufacturing, also known as 3D printing, allow for complex geometries and miniaturization that traditional methods struggle to achieve. This capability is crucial for developing compact devices that maintain performance in an increasingly connected world.

Additionally, processes like laser drilling and high-density interconnect (HDI) technology are transforming how circuit boards are constructed. Laser drilling provides precision and supports the creation of intricate pathways that facilitate faster signal transmission—an essential requirement for 5G applications. Meanwhile, HDI technology allows for more functionality to be packed into a smaller footprint, making it ideal for IoT devices that require numerous functions within tight design constraints. As these advanced fabrication techniques evolve, they continue to drive the innovation necessary for the next generation of electronic devices.

Key Innovations in Circuit Board Design for 5G and IoT Applications

The evolution of circuit board design is crucial in supporting the rapid advancement of 5G and IoT technologies. Recent industry reports indicate that the global IoT connections are anticipated to exceed 75 billion by 2025, reflecting an explosive growth in demand driven by smarter applications and connectivity solutions. The integration of advanced materials and manufacturing techniques in circuit board fabrication is necessary to meet these demands while ensuring efficiency and reliability.

Flex printed circuit boards (FPCs) are gaining traction in the market, with forecasts suggesting a robust compound annual growth rate above 8% from 2024 to 2032. These innovative designs enable lightweight, space-saving solutions that are essential for the compactness of IoT devices. As companies embrace 5G connectivity, the development of high-frequency circuit boards becomes imperative. Innovations in design and fabrication not only improve performance but also enhance the overall user experience by enabling faster data rates and more stable connections. This trend underscores the intersection of material science and electronics, propelling the digital economy into a new era.

Implementing Sustainable Practices in Circuit Board Manufacturing

As the electronics industry evolves alongside 5G and IoT innovations, the implementation of sustainable practices in circuit board manufacturing becomes paramount. The growing demand for efficient and eco-friendly production methods drives manufacturers to integrate advanced technologies, such as AI and automated processes, into their operations. These innovations not only streamline production but also significantly reduce waste and energy consumption, aligning with global sustainability goals.

**Tips:** Embracing AI can enhance operational efficiency by predicting maintenance needs and optimizing resources. Additionally, consider adopting closed-loop manufacturing systems to recycle materials and components, minimizing environmental impact.

The market trends indicate a shift towards smarter manufacturing solutions, particularly in PCB production. By investing in digitization and advanced circuit techniques, companies can enhance product quality while meeting the rigorous standards required for high-performance electronics. As the industry continues to explore new territories, innovative approaches to sustainability will play a crucial role in shaping the future of circuit board fabrication.

**Tips:** Collaborate with technology partners to access the latest advancements in production techniques, and regularly assess your supply chain for opportunities to enhance sustainability.

Impact of 5G and IoT on Circuit Board Manufacturing

This bar chart illustrates the growth in global circuit board production from 2019 to 2023, highlighting the significant impact of 5G and IoT innovations on the electronics industry. The steady increase reflects advancements in technology and the rising demand for efficient circuit board fabrication processes.

Choosing the Right Materials for Enhanced Performance in Electronics

The rapid advancements in 5G and Internet of Things (IoT) technologies have intensified the demand for innovative circuit board fabrication methods. One crucial aspect that directly influences the performance of electronic devices is the selection of materials used in circuit board manufacturing. According to the International Journal of Electronics and Telecommunications, high-frequency applications, such as 5G, require materials with low dielectric loss and stable thermal properties to ensure optimal signal integrity and thermal management.

When choosing materials, consider using advanced resin systems and fillers that can withstand the high speeds and electromagnetic compatibility essential in modern electronics. For example, materials like Rogers RT/duroid and Taconic, known for their excellent dielectric properties, are increasingly favored in high-frequency applications. Furthermore, using high-performance laminates such as FR-4 can provide the necessary balance of cost and performance for many applications.

**Tips:** Always assess the specific requirements of your application, including frequency and environmental conditions, to select the most appropriate materials. For manufacturers, investing in multi-layered designs can significantly enhance reliability and performance. Regular material testing and compliance with industry standards can also help reinforce the quality of your circuit boards as 5G and IoT continue to evolve.

Future Trends in Circuit Board Fabrication and Their Impact on Technology

The printed circuit board (PCB) market is positioned for significant growth, bolstered by advances in technology and the increasing demand for 5G and IoT applications. According to the industry report, the global PCB market is set to reach approximately $880 billion in 2024, up from $783.4 billion in 2023, reflecting a robust annual growth rate. By 2033, it is anticipated that this market will further expand to $1.1 trillion, showcasing a compound annual growth rate (CAGR) of 4.3%. This growth trajectory is fueled by innovations in electronics, particularly in the automotive sector, where the PCB market is expected to escalate from $9.15 billion in 2023 to $15.1 billion by 2032, indicating a CAGR of 5.9%.

As China leads the way in PCB production, the influx of artificial intelligence technologies presents new opportunities for the industry. The trends suggest a paradigm shift in manufacturing, driven by smart devices and enhanced production logic. The focus on automotive technologies and increasing safety measures on roads further underscores PCB's critical role in future electronic advancements. With the global electronics manufacturing landscape on the brink of a technological revolution, these emerging trends highlight the need for advanced circuit board fabrication that supports the next generation of connected devices.

Related Posts

-

Challenges Associated with Sourcing the Best Computer Circuit Board

-

Global Procurement of Top-Tier PCB Prototype Boards: China's Manufacturing Excellence Unleashed

-

Essential Checklist for Choosing the Best Pcb Printed Circuit Board for Your Project

-

Innovative Approaches for Optimal Pcb Board Fabrication Success

-

The Ultimate Guide to Optimizing Printed Board Assembly for Maximum Efficiency and Cost Savings

-

Top Strategies for Optimizing Your Printing Circuit Boards Production Process