JHY PCB Blog Hub

Your Source for Expert PCB Design, Manufacturing, and Assembly Insights – Stay Informed with 2025 Trends!

Navigating the 2025 Tech Landscape: Key Strategies for Sourcing the Best PCB Circuit Boards Globally

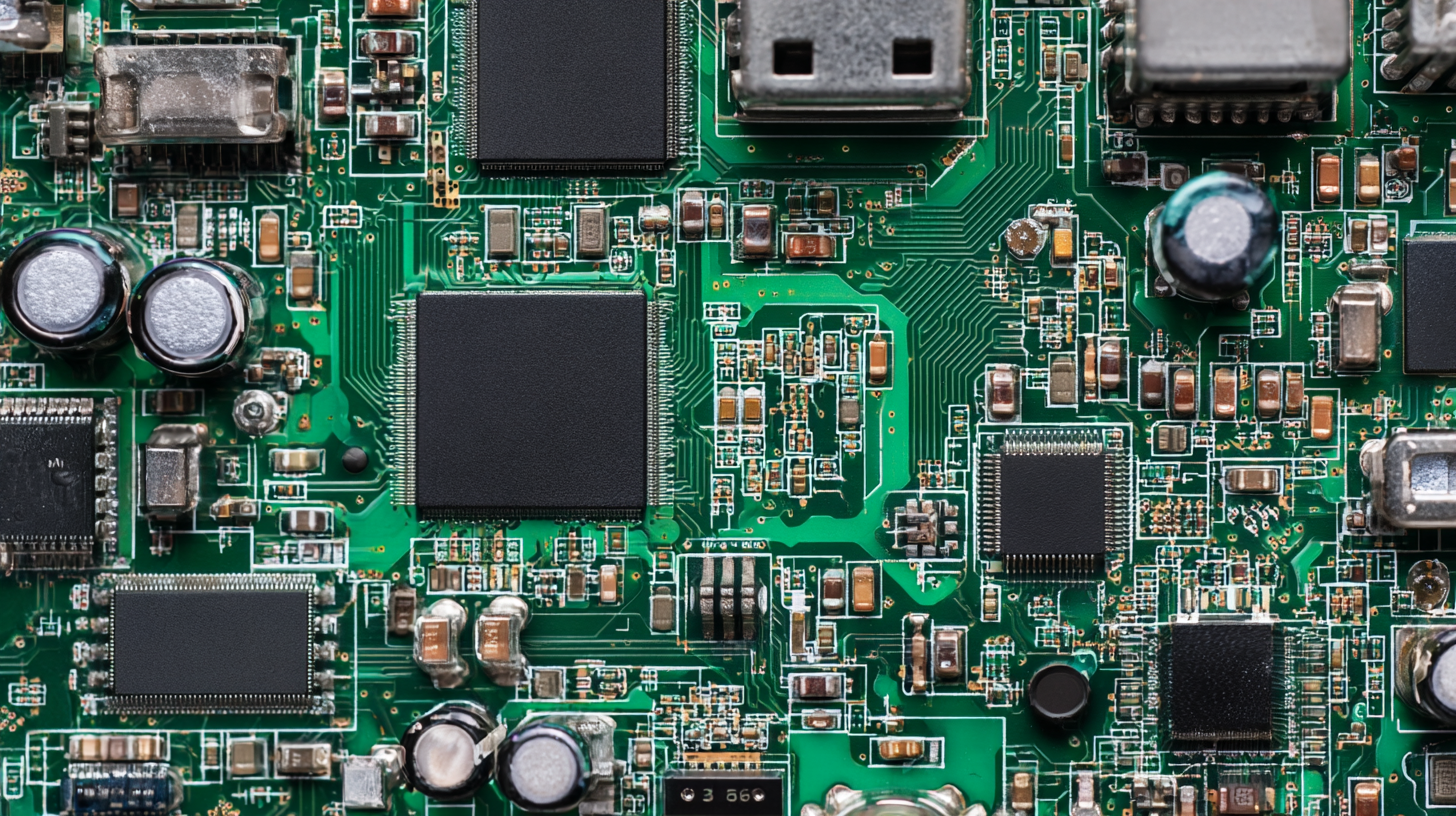

In the rapidly evolving technology landscape of 2025, businesses are faced with the challenge of sourcing high-quality PCB circuit boards that meet their diverse requirements. With the mantra "Made in China, Shared Globally, Quality You Can Trust," the significance of China as a leading manufacturer in the electronics industry cannot be overstated.

As companies aim to stay competitive, understanding key strategies for navigating the global market for PCB circuit boards is essential. This blog explores the pivotal factors influencing sourcing decisions, including quality assurance, supply chain agility, and collaboration with trusted manufacturers.

By leveraging these strategies, businesses can ensure they not only obtain superior PCB circuit boards but also foster long-lasting partnerships that enhance their overall product offerings in an increasingly interconnected world.

Identifying High-Quality PCB Manufacturers in a Competitive Market

In today’s highly competitive market, sourcing high-quality PCB manufacturers is crucial for maintaining a technological edge. With an overwhelming number of suppliers available globally, the challenge lies in distinguishing those that offer superior reliability and quality. Start by leveraging industry connections and attending trade shows, where you can interact directly with manufacturers and review their products firsthand. Additionally, online platforms and directories can provide valuable insights and ratings based on real user experiences.

Tip: Always request samples from prospective manufacturers before making bulk orders. This hands-on approach allows you to evaluate their production standards, materials, and overall precision. Moreover, don't hesitate to ask about their certifications, as reputable manufacturers will have ISO or IPC certifications that ensure adherence to industry standards.

When researching PCB manufacturers, consider their experience and specialization in your specific application. For instance, some may excel in high-frequency PCBs while others are better suited for consumer electronics.

Tip: Utilize social media and forums to gather recommendations and feedback from peers who have worked with various manufacturers. Their insights can guide you toward making informed decisions while avoiding potential pitfalls in your sourcing journey.

Leveraging Digital Tools to Evaluate PCB Circuit Board Suppliers

In the rapidly evolving tech landscape of 2025, sourcing high-quality PCB circuit boards requires a strategic approach, especially when considering the multitude of global suppliers. Leveraging digital tools is critical to efficiently assess potential partners. According to a recent Market Research Future report, the global PCB market is projected to reach $82 billion by 2025, highlighting the increasing demand and competitive nature of the industry. This necessitates a thorough evaluation process to identify suppliers who can meet specific technical and quality standards.

Digital platforms, such as supplier evaluation software and online marketplaces, can streamline the procurement process. A study by Gartner indicates that companies using digital sourcing solutions can reduce procurement costs by up to 20%. These tools enable procurement teams to perform due diligence on potential PCB suppliers by analyzing performance metrics, certifications, and customer reviews in real time. By adopting a data-driven approach, businesses can enhance their sourcing strategy, ensuring they choose suppliers that not only offer competitive pricing but also adhere to the quality and safety standards vital in the electronics sector.

Navigating the 2025 Tech Landscape: Global PCB Supplier Evaluation Metrics

Understanding Certifications and Industry Standards for PCB Quality Assurance

When sourcing PCB circuit boards in 2025, understanding the certifications and industry standards is paramount for ensuring quality and reliability. According to a recent Market Research Future report, the global PCB market is projected to reach $89 billion by 2025, with a significant emphasis on quality assurance driven by competitive pressures. Manufacturers are increasingly seeking PCBs that comply with international standards such as IPC-A-600, which provides guidelines for the acceptability of printed boards. This certification is crucial, as it directly impacts the longevity and performance of electronic devices across various sectors, including automotive and consumer electronics.

In addition, adherence to ISO 9001 quality management systems is vital for PCB suppliers aiming to enhance customer satisfaction and streamline operations. A study by the IPC found that companies with ISO 9001 certifications report a 20% increase in operational efficiency and a notable decrease in defect rates. As sourcing partners become more discerning, companies that prioritize these certifications not only gain a competitive edge but also ensure that their products meet the stringent demands of an evolving tech landscape. Navigating the complex world of PCB sourcing has never been more critical, and understanding these industry standards is the first step towards achieving that goal.

Best Practices for Comparing PCB Manufacturing Costs without Sacrificing Quality

In the ever-evolving landscape of electronics, sourcing printed circuit boards (PCBs) has become a critical task for manufacturers aiming to optimize both cost and quality. A recent report from IPC shows that the global PCB market is projected to reach $80 billion by 2025, emphasizing the necessity for businesses to develop strategies that ensure cost-effectiveness without compromising on the quality of materials used. Given the complexity of PCB production, the comparison of manufacturing costs across different suppliers can be challenging but essential.

Tip 1: When evaluating PCB manufacturers, consider utilizing a cost breakdown analysis. This approach helps to identify hidden costs, such as tooling fees or material markups, which can significantly affect the overall expense. By asking for detailed quotes, including all aspects of the production process, companies can make informed comparisons that highlight true cost-effectiveness.

Furthermore, maintaining an open line of communication with potential manufacturers can enhance the sourcing experience. According to a survey by Mentor Graphics, 57% of companies report that collaboration with suppliers leads to better product outcomes. Establishing strategic partnerships and leveraging technology for real-time discussions can facilitate negotiation, ultimately leading to favorable pricing while ensuring quality standards are upheld.

Establishing Long-Term Relationships with Global PCB Suppliers for Consistency

Establishing long-term relationships with global PCB suppliers is crucial for ensuring consistency in quality and delivery. These partnerships can significantly enhance your supply chain resilience, allowing for smoother operations and reduced lead times. To cultivate these relationships, maintain open lines of communication with your suppliers, discussing not only current projects but also future developments and potential challenges.

**Tip 1:** Schedule regular check-ins with your suppliers to review performance metrics and address any issues promptly. This proactive approach fosters trust and encourages collaboration, making your suppliers feel valued and invested in your success.

**Tip 2:** Consider implementing a vendor evaluation system that assesses suppliers based on quality, reliability, and responsiveness. Sharing this feedback helps suppliers improve and aligns their goals with yours, creating a win-win situation for both parties.

Through these efforts, you pave the way for a sustainable and efficient sourcing strategy that can adapt to changes in the tech landscape, ensuring your business remains competitive in 2025 and beyond.